Simplified, Harmonized Hazard Communication Standard Now in Effect

Posted on Sep 24, 2015If you work with agricultural chemicals or other potentially dangerous materials, including pesticides, herbicides, fertilizers, diesel fuel and/or disinfectant products, you should understand the new label requirements and Safety Data Sheet (SDS) format. As of June 1 of this year, all chemical manufacturers are required to use a new labeling and the SDS format established under Globally Harmonized System (GHS) criteria for classifying the health and physical hazards of the chemicals they produce. By June 1, 2016, employers must update workplace labeling and hazard communication programs, providing ongoing employee training for newly identified physical or health hazards. Here are some things you should know about the new labels and SDSs: Hazard definitions are now more specific, ensuring consistency across the board. There are more specific criteria for classification of health and physical hazards and for the classification of mixtures.

Labels now need to include six standard elements for classified hazards: product identifier, manufacturer contact information, hazard pictograms, signal word (DANGER or WARNING), hazard statements and precautionary statements. The SDS format, formerly the Material Safety Data Sheet (MSDS), is now the key Hazard Communication Standard (HCS). The information required on the SDS is essentially the same as the former MSDS; however, it will now be required to be organized in a specific 16-section format.

Labels now need to include six standard elements for classified hazards: product identifier, manufacturer contact information, hazard pictograms, signal word (DANGER or WARNING), hazard statements and precautionary statements. The SDS format, formerly the Material Safety Data Sheet (MSDS), is now the key Hazard Communication Standard (HCS). The information required on the SDS is essentially the same as the former MSDS; however, it will now be required to be organized in a specific 16-section format.

- -Sections 1 – 8 of the SDS contain general information about the chemical identification, hazards, composition, safe handling practices and emergency control measures.

- -Sections 9 – 16 contain other technical and scientific information, including the date of preparation or last revision.

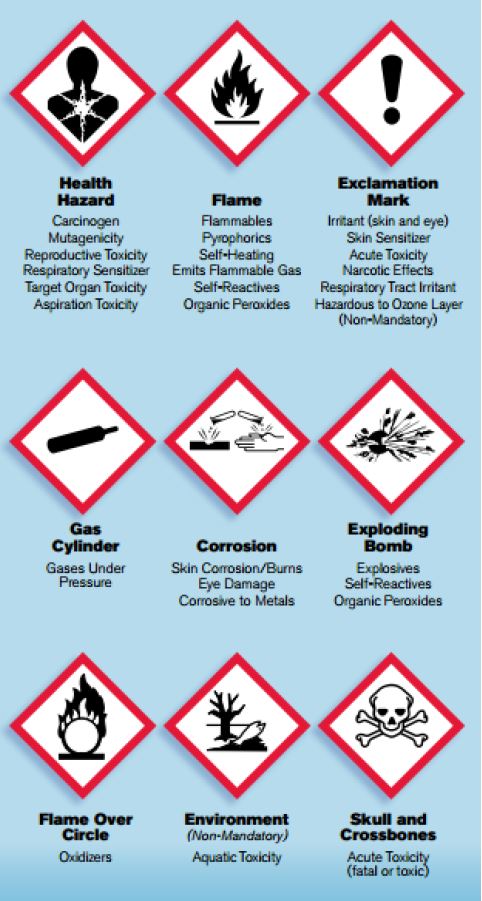

What do chemical users need to do? First and foremost, always read and follow the packaging label and SDS. Chemical users and their employers should continue to update their files with the new Standard Data Sheets as they become available. Update hazard communications programs if new hazards associated with the chemicals used in your operation are identified. You should also familiarize yourself with the nine pictograms and what they stand for so you know what types of hazards you are dealing with.

- -According to the Center for Food Security and Public Health at Iowa State University, here are some basic tips to prevent chemical injury and exposure:

- -Guard against splashes, spills and skin contact when mixing, handling and applying chemicals. At a minimum, wear long pants, long sleeves (or coveralls) and enclosed shoes.

- -Wear additional protective equipment as recommended by the label. This may include chemicalresistant gloves, goggles and/or a face shield and an approved respirator.

- -Mix and prepare products in a well-ventilated area.

- -Use only the amount and concentration specified by the label.

- -Do not mix different products unless allowed by label directions.

- -Launder chemical-soiled clothing separately from other laundry, and triple rinse.

- -Avoid inhaling sprays, dust and vapors.

The Center for Food Security and Public Health also provides some best practices for safe chemical storage:

- -Limit storage areas to the minimum needed to discourage storing unnecessary chemicals.

- -Store chemicals in a secure area. Keep them in locked, weatherproof areas located above ground to prevent moisture problems, like rusting and disintegration. Locate storage areas at a safe site that will not be subjected to flooding. Make sure the area is well lit with a sign indicating the area contains chemicals, and provide at least two emergency contact numbers. Keep storage areas dry and well ventilated, avoiding freezing and extreme high temperatures. Keep chemicals out of reach of children and pets.

- -Store chemicals in their original containers. Keep the containers tightly closed and clearly labeled. If labels become worn or damaged, re-label the container with its contents or discard the chemical. Never store chemicals in damaged containers, and never use food or beverage containers to store chemicals.

What are the benefits of the new standard? There are more than 43 million workers who produce or handle hazardous chemicals in more than 5 million workplaces across the country. These new standards are expected to prevent as many as 500+ injuries and illnesses and 43 fatalities. The new standard is a more consistent hazard information source in the workplace and the format is easier for workers to comprehend. The productivity improvements, fewer SDS and label updates, and the new, simpler hazard communication training are expected to save American businesses more than $500 million. All of these changes are ultimately intended to make users more aware of the products they are dealing with so that they safely utilize them. For more information about the new HCS, visit the Grainger GHS compliance site.

Press release courtesy of AFBF.

Sources: 1. “Are You Ready? GHS Hazard Communication Standard Final Rule,” W.W. Grainger, Inc. 2013. http://static.grainger.com/images/GHS-Standard-Rule.pdf 2. “Agrochemicals on Your Farm: Safety,” The Center for Food Security and Public Health, Iowa State University College of Veterinary Medicine. http://www.prep4agthreats.org/Assets/Factsheets/Agrochemicals-on-Your-Farm-Safety.pdf

Tagged Post Topics Include: Accident, Environment, Explosion, Flamable, Globally Harmonized System, Hazard Communication Standard, Hazardous, Health, Material Safety Data Sheet, Regulations, Safety, Safety Data Sheet

Comments